JDM Tuners Revealed: Inside the Workshops Defining Japanese Performance

Go inside the legendary workshops and master tuners shaping JDM culture. Discover the philosophies, techniques, and dedication behind magazine-worthy builds from Japan's finest specialists.

TL;DR: Key Takeaways

-

Master JDM tuners combine decades of experience with continuous innovation, creating builds that balance performance, reliability, and aesthetic excellence

-

Successful workshops develop signature approaches and philosophies that distinguish their builds while maintaining the technical rigor that defines JDM culture

-

The relationship between tuners and JDM car magazines like Stance Auto helps document best practices and elevate standards across the entire community

Behind every exceptional JDM car featured in magazines like Stance Auto lies a workshop where skilled tuners, fabricators, and technicians transformed good vehicles into genuinely special ones through combinations of technical knowledge, hands-on experience, refined aesthetic sensibilities, and the particular dedication to excellence that distinguishes professional craftsmen from enthusiastic amateurs. These workshops represent the heart of JDM tuners culture—places where engineering meets artistry, where decades of accumulated knowledge gets applied to solving specific challenges, and where the standards that define exceptional work get maintained and continuously refined through each project and every build that rolls through their facilities.

Understanding what happens inside these workshops, how master tuners approach various challenges, and what separates facilities producing magazine-worthy builds from countless others offering similar services provides invaluable insights for enthusiasts planning their own projects, evaluating potential builders for commissioned work, or simply wanting deeper appreciation for the skill and effort required to transform factory JDM cars into the extraordinary machines that grace magazine pages and dominate track days, car shows, and enthusiast conversations across the global Japanese performance community.

The Philosophy: More Than Just Bolt-On Modifications

What immediately distinguishes elite JDM tuners from basic modification shops involves their fundamental approach to builds—they think systematically rather than simply installing parts customers request without considering broader implications or questioning whether those choices actually serve the vehicle's intended purpose. A customer might arrive requesting a specific turbocharger based on internet research or peer recommendations, but a skilled tuner will ask questions about intended use, performance goals, budget constraints, and timeline expectations before potentially suggesting alternatives better suited to the actual requirements rather than perceived desires shaped by incomplete information or unrealistic expectations about what particular modifications will deliver.

This consultative approach extends throughout the build process, with master tuners educating clients about why certain supporting modifications become necessary when pursuing specific power levels, how various components interact within larger systems, and what tradeoffs different approaches entail regarding reliability, drivability, maintenance requirements, and ultimate performance characteristics. The best workshops don't simply execute customer instructions—they collaborate with owners to develop build plans that realistically achieve stated goals while avoiding common mistakes that less experienced builders make repeatedly, wasting money on inappropriate components or creating vehicles that perform impressively on paper but prove frustrating or unreliable in actual use.

Technical Expertise: The Foundation of Excellence

The technical knowledge base at facilities producing magazine-quality JDM classics builds extends far beyond what most enthusiasts realize—master tuners understand not just how to install components but why particular parts work effectively for specific applications, what failure modes various modifications introduce, and how to anticipate and address problems before they manifest. This depth of knowledge comes primarily through experience rather than formal education, accumulated across thousands of hours working on similar platforms, learning from both successes and failures, and maintaining the intellectual curiosity that drives continuous learning rather than simply repeating established formulas without understanding underlying principles.

Workshops featured prominently in publications like Stance Auto Magazine demonstrate this expertise through their diagnostic capabilities, quickly identifying issues that would stymie less experienced technicians, and through their problem-solving creativity when confronting unusual challenges or developing solutions for vehicles where established procedures don't exist or proven parts aren't readily available. This technical mastery manifests in details—the cleanliness of wiring installations, the thoughtfulness of component placement considering heat management and serviceability, the attention to potential failure points that get reinforced before problems occur rather than being addressed reactively after failures happen.

Specialization Versus Generalization: Finding Your Niche

The JDM tuners landscape includes both specialists focused intensely on particular platforms or modification types and generalists offering broad capabilities across multiple makes and models. Each approach has merits—specialists develop unmatched depth of knowledge about specific vehicles, accumulating tips, tricks, and solutions to problems that more general facilities might not even recognize as potential issues. A shop specializing exclusively in RB-series Nissan engines, for instance, will understand minute details about oiling system weaknesses at various power levels, which internal components tolerate specific boost pressures, and how different engine management strategies affect reliability and performance characteristics in ways that generalist facilities, even highly competent ones, simply cannot match without that focused experience.

Conversely, generalist workshops bring broader perspectives and can apply solutions developed on one platform to challenges encountered with different vehicles, cross-pollinating ideas and approaches across the JDM cars spectrum in ways that sometimes produce innovative solutions that specialists, working entirely within one ecosystem, might not consider. The most successful generalist shops maintain quality by limiting scope to vehicle types where they've developed genuine expertise rather than accepting every project that arrives regardless of whether they truly possess the specialized knowledge required for excellence. This discipline distinguishes facilities that consistently produce exceptional work from those that occasionally create impressive builds but lack the consistency that defines true mastery.

The Role of Testing and Development

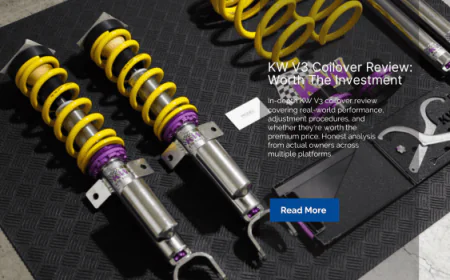

Elite workshops don't simply install parts and send vehicles away—they invest significant resources in testing and development that ensures modifications perform as intended and that vehicles leave the facility in genuinely improved condition rather than simply being different from stock. This commitment to validation manifests through dyno testing that confirms power delivery and identifies issues before they cause problems, track testing that reveals handling characteristics under demanding conditions, and extended road testing that evaluates how modifications affect daily drivability, comfort, and the overall ownership experience beyond pure performance metrics.

This testing infrastructure represents substantial investment that smaller or less serious facilities cannot justify, but it's essential for producing the consistent, reliable results that build reputations and earn magazine coverage. When Stance Auto features a build from a particular workshop, implied in that coverage is confidence that the vehicle genuinely performs well rather than simply looking impressive or achieving numbers on a dyno without being functional in real-world conditions. The testing process also generates knowledge that informs future projects—understanding exactly how specific modifications affect various performance parameters allows tuners to make more accurate predictions and recommendations for subsequent builds, continuously refining their approaches based on empirical data rather than assumptions or manufacturer claims that may not reflect real-world results.

Fabrication Capabilities: Custom Solutions

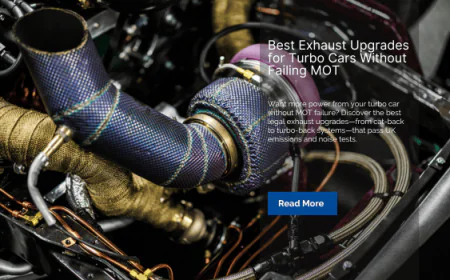

While many modifications involve installing aftermarket components, the workshops producing truly exceptional JDM legends builds possess fabrication capabilities that allow custom solutions when off-the-shelf parts don't exist or don't meet the specific requirements of particular projects. This might involve custom exhaust manifolds optimized for specific turbocharger choices and packaging constraints, one-off suspension components addressing geometry issues that standard parts cannot correct, or custom engine mounts that allow unusual engine swaps while maintaining proper positioning and vibration isolation.

These fabrication skills distinguish workshops producing magazine-worthy builds from basic installation facilities—the ability to create rather than simply assemble means solutions exist for virtually any challenge rather than being limited to whatever manufacturers have decided to produce. This capability also enables continuous refinement, with fabricators producing multiple iterations of particular components, testing each, and evolving designs based on real-world results rather than being locked into whatever a parts manufacturer offers and hoping it works adequately. The craftsmanship evident in custom fabrication also serves aesthetic functions, with professionally executed work being visually distinctive even to casual observers while poorly executed custom work immediately signals lower standards regardless of how functional it might be.

Engine Building: The Heart of Performance

For many JDM tuners, engine building represents their most critical competency—the ability to take factory powerplants and transform them into reliable, powerful units that withstand abuse far beyond what manufacturers designed for while maintaining the drivability and character that make Japanese performance engines so celebrated. Master engine builders understand the intricate relationships between compression ratios, camshaft timing, fuel delivery, and boost pressure, knowing exactly how far various platforms can be pushed before reliability compromises become unacceptable or when diminishing returns mean additional investment produces minimal performance improvement.

The engine building process at serious facilities follows rigorous procedures—comprehensive inspection of all components, precise measurement and matching of parts to ensure proper clearances and tolerances, meticulous assembly following specific torque sequences and specifications, and thorough break-in procedures that set the stage for long-term reliability. These protocols, while time-consuming and expensive, distinguish engines that deliver reliable performance over thousands of miles from those that make impressive power briefly before failing due to shortcuts taken during assembly or component quality issues that should have been identified before installation. Engine building expertise also extends to diagnosis and repair, with experienced builders quickly identifying failure causes and implementing solutions that address root problems rather than simply replacing failed parts without understanding why they failed.

The Business Reality: Quality Versus Volume

Operating a successful JDM tuning workshop requires balancing quality standards with business realities—the most meticulous work takes time that creates pricing structures beyond what many enthusiasts can afford, while rushing through projects to increase volume inevitably compromises quality and leads to the problems and failures that destroy reputations. The workshops consistently producing magazine-quality builds have generally resolved this tension by positioning themselves as premium providers, charging rates that reflect the genuine value they deliver through experience, expertise, and the lower risk of problems compared to cheaper alternatives that might initially seem more affordable but often result in higher total costs after addressing issues that proper initial work would have prevented.

This premium positioning means accepting fewer projects but executing each to standards that maintain reputation and generate the word-of-mouth referrals that sustain businesses long-term. It also means occasionally declining projects—turning away customers whose expectations don't align with reality, refusing builds that would require compromising standards to meet unrealistic budgets or timelines, or simply acknowledging when particular projects fall outside the workshop's genuine expertise rather than accepting work they're not truly equipped to execute excellently. This discipline in client selection distinguishes sustainable, reputable facilities from those that take every project regardless of whether they can genuinely deliver quality results.

Relationships With Parts Manufacturers and Suppliers

Elite JDM tuners typically maintain close relationships with parts manufacturers and specialized suppliers, providing them access to components before they reach general market, input during development processes, and often preferential pricing that helps them remain competitive while using premium parts that deliver better results than cheaper alternatives. These relationships benefit manufacturers through field testing and the marketing value of having respected builders using their products in featured builds, while workshops benefit from improved component quality, technical support when issues arise, and the insider knowledge about which new products genuinely improve on existing options versus being primarily marketing-driven releases offering minimal actual advantages.

These partnerships also enable collaborative problem-solving when workshops encounter challenges with particular applications or discover limitations in existing products—manufacturers can develop solutions or modifications based on real-world feedback from builders working with their products daily rather than relying solely on their own testing, which might not replicate the full range of conditions and applications that customers subject vehicles to. The strongest relationships involve mutual respect and genuine collaboration rather than simply transactional arrangements, with manufacturers valuing tuner expertise and feedback while tuners appreciate manufacturers' engineering capabilities and willingness to support professional builders with technical resources and warranty support that make recommending their products less risky.

Documentation and Knowledge Sharing

The best workshops recognize value in documenting their work and sharing knowledge with the broader JDM community, contributing to the collective understanding that elevates standards across the entire scene. This manifests through detailed build threads on enthusiast forums, technical articles explaining specific procedures or modifications, participation in magazine features like those in Stance Auto Magazine, and educational content through video platforms or social media that helps enthusiasts understand what professional-quality work involves and what they should expect when commissioning builds from reputable facilities.

This knowledge sharing might seem counterintuitive from a business perspective—why educate potential customers in ways that might enable them to perform work themselves or make them more critical of the work they're paying for? The reality is that educated customers make better clients—they have more realistic expectations, they appreciate the value that expertise delivers, and they understand why proper work costs what it does rather than simply seeking the cheapest option without understanding quality differences. Educated enthusiasts also make better ambassadors, providing accurate information within their communities and steering potential customers toward reputable builders rather than allowing misinformation and poor recommendations to damage the industry's reputation overall.

The Workshop Environment: Culture and Standards

The physical environment and internal culture at exceptional workshops reflect their commitment to quality—these facilities maintain organization that allows efficient work without wasting time searching for tools or dealing with clutter, they invest in proper equipment rather than making do with inadequate tools that compromise results or efficiency, and they foster cultures where everyone from master technicians to apprentices understands that every detail matters and that the shop's reputation depends on consistent excellence rather than occasionally impressive results mixed with mediocre work.

This culture manifests in how employees interact with vehicles—respect for customer property, care in handling components, attention to cleanliness that prevents contamination during engine assembly or paint work, and the professionalism that treats every project, regardless of budget or scope, as deserving of their best efforts. Creating and maintaining this culture requires leadership from workshop owners and master technicians who model desired behaviors, provide training and mentorship that develops skills in less experienced staff, and enforce standards consistently rather than tolerating shortcuts or carelessness that gradually erode quality over time.

International Influence and Cross-Cultural Exchange

While JDM tuners culture originates in Japan, leading workshops now exist globally, with facilities in the UK, Europe, North America, and Australia developing their own expertise while maintaining connections to Japanese domestic market specialists through parts sourcing relationships, occasional collaborations, and shared participation in the international enthusiast community. This global network enables knowledge exchange where techniques developed in one region spread to others, where parts availability challenges faced in markets distant from Japan get solved through local fabrication or alternative sourcing, and where builds from different regions influence each other aesthetically and technically.

The best international workshops maintain respect for the Japanese roots of JDM classics culture while adapting to local conditions, regulations, and preferences in ways that honor source material without simply attempting to replicate Japanese builds in contexts where such direct replication might not be optimal. Understanding this balance—respecting heritage while acknowledging that vehicles built for UK roads don't need identical specifications to those built for Japanese circuits or streets—demonstrates sophistication that distinguishes thoughtful builders from those who simply copy without understanding the reasoning behind original choices or how different contexts might require different approaches to achieve similar goals.

For those interested in exploring how magazines document these workshops and their evolution over time, Four Years of JDM Excellence: The Complete Stance Auto Magazine Archive provides comprehensive perspective on how consistent coverage reveals workshop development, signature styles, and the accumulation of expertise that distinguishes master tuners from competent professionals.

Conclusion: The Human Element Behind Magazine Features

Understanding JDM tuners and the workshops they operate transforms how enthusiasts appreciate magazine features and the vehicles showcased within them—these builds aren't simply collections of parts installed by interchangeable technicians but rather reflections of particular philosophies, accumulated knowledge, and the dedication of specific individuals whose skills, experience, and commitment to excellence produced machines worthy of documentation in publications like Stance Auto Magazine. This human element enriches appreciation for featured builds while also providing practical guidance for enthusiasts seeking builders for their own projects, helping them understand what questions to ask, what standards to expect, and how to identify facilities capable of delivering results matching their goals and budgets.

The workshops profiled in this exploration represent just a fraction of the talented builders working within JDM culture globally, but they exemplify the characteristics and approaches that distinguish exceptional work—technical mastery combined with aesthetic sensibility, business acumen that balances quality with sustainability, and genuine passion for Japanese performance vehicles that extends beyond simply making money to encompass pride in craftsmanship and commitment to advancing the culture rather than merely participating in it. For anyone serious about builds worthy of magazine coverage or simply wanting to better understand what makes certain vehicles and builders special, engaging with these workshops' philosophies and approaches provides invaluable education and inspiration.

Want More JDM Icons?

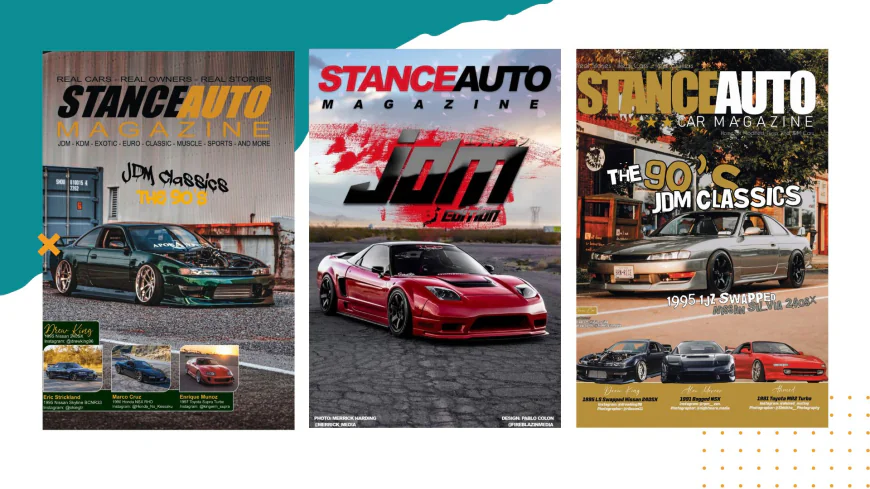

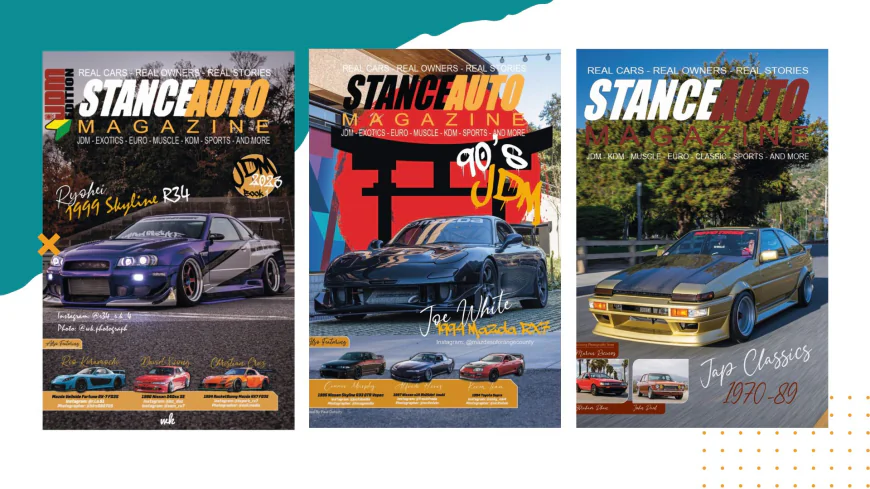

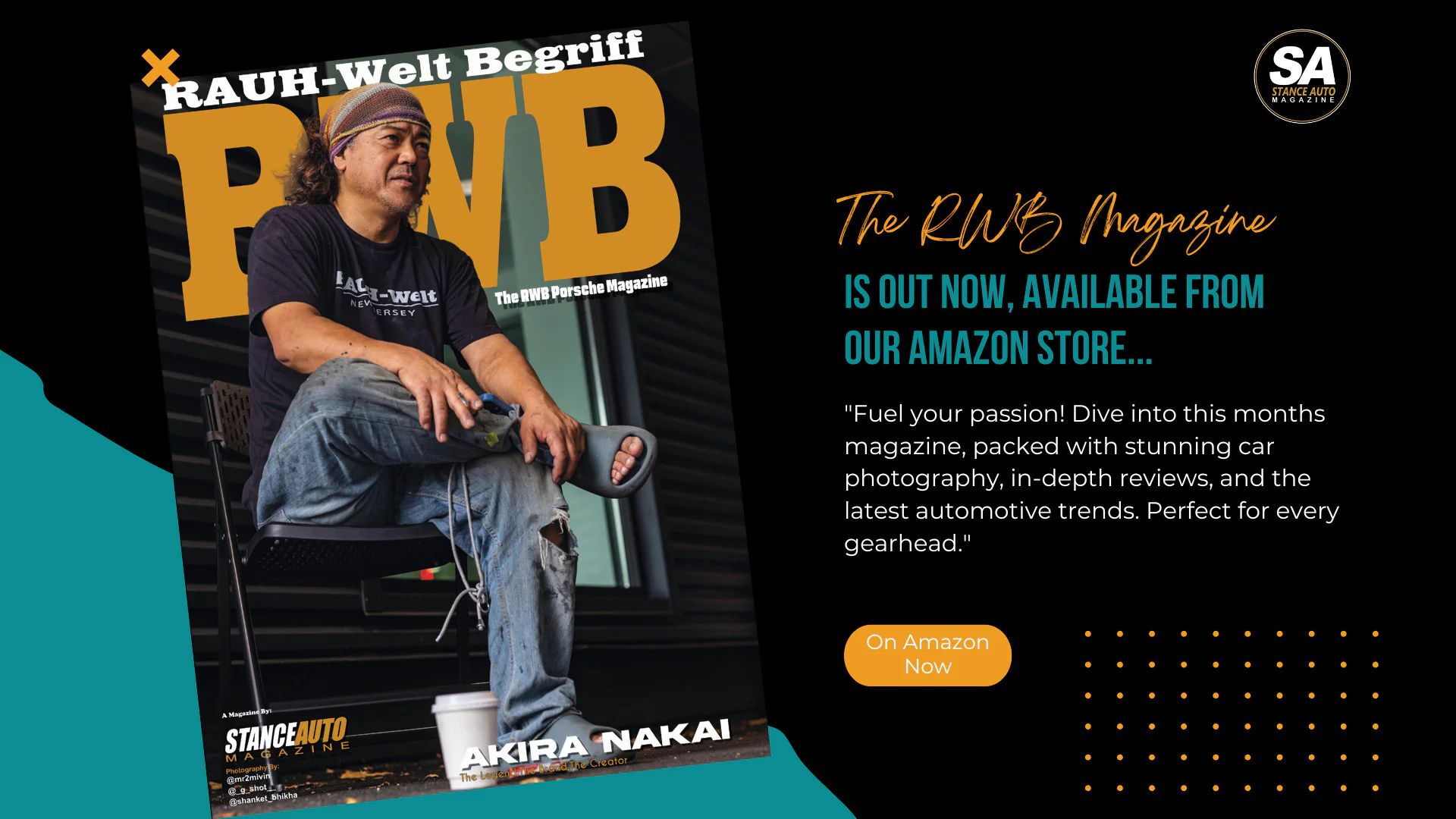

If you love stories like this one, you will enjoy our featured magazines available on Amazon

- Stance Auto Magazine Japanese Classic Cars Vol2: Modified Japanese Classic JDM Cars Magazine

- Stance Auto Magazine July 2025: A Worldwide Monthly Modified Car Magazine

- Modified Car Magazine The JDM Magazine: The World Wide Modified JDM Car Magazine

- Stance Auto Magazine The 90's JDM Classics - June 2025: A look Back At The 90's Classic JDM Cars On Stance Auto

- Stance Auto Magazine Modified BMW'S 2025: The Modified and Tuner BMW Car Magazine

- The RWB Porsche Magazine From Stance Auto: Akira Nakai The Man Behind The RWB Builds

- Stance Auto Magazine JDM Classics The 90s

These print editions showcase incredible builds like Lucas’s GT-R while supporting the global modified car community.

Call to Action

Do you have a build story like this one? Got a build on a budget? We want to see it. Submit your story to Stance Auto Magazine, and you could be the next featured owner showing the world how to do it right—without breaking the bank.

And hey, don’t forget to tag us on socials. Use #stanceautomag on Instagram, Pinterest and Facebook so we can see (and maybe feature) your ride.

Test Your JDM Car Knowledge and Take Our No. 1 JDM Car Quiz

Order Your Stance Auto Car Magazines From Our Amazon Book Store

Test Your Automotive Knowledge and Take Our No. 1 Car Quiz

Get Noticed Use our Hashtags - #stanceauto #stanceautomag #stanceautomagazine #modifiedcarmagazine

UKTM no: UK00003572459

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0

.png)

![[HOONIGAN] Ken Block's GYMKHANA NINE](https://img.youtube.com/vi/_bkX5VkZg8U/maxresdefault.jpg)

![[HOONIGAN] KEN BLOCK'S GYMKHANA SEVEN: WILD IN THE STREETS OF LOS ANGELES](https://cdn.motor1.com/images/mgl/2KlO4/s1/ken-block-london-tour-directors-cut.jpg)