2JZGTE Build Guide: Parts, Tuning, and Reliability

Complete 2JZGTE build guide covering stock specs, power levels, essential parts, tuning strategies, and reliability limits. Factual data from real-world builds for street and track applications.

TL;DR - Key Takeaways

-

Stock 2JZGTE bottom end reliably handles 600-700hp with proper tuning; built engines exceed 1,000hp

-

Factory sequential twin turbos max out around 400hp before single turbo conversions unlock serious power

-

Cast-iron block, forged crank, and robust internals make the 2JZ legendary for durability

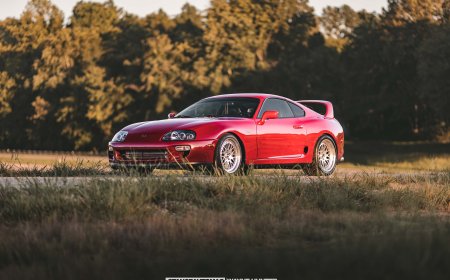

The Toyota 2JZGTE isn't just another engine—it's become the gold standard by which all tuner engines are measured. When Toyota designed this 3.0-liter twin-turbocharged inline-six between 1991 and 2005, they overbuilt it in ways that would make accountants cry but have made enthusiasts smile for three decades. The result is an engine that can double or triple its factory output while maintaining reliability that modern powerplants struggle to match.

Walk into any serious tuning shop, and you'll find 2JZ engines producing 700, 800, even 1,000+ horsepower on blocks that left the factory planning for 320 horsepower. This isn't luck or hype—it's the result of specific engineering choices that created an almost bulletproof foundation for modification.

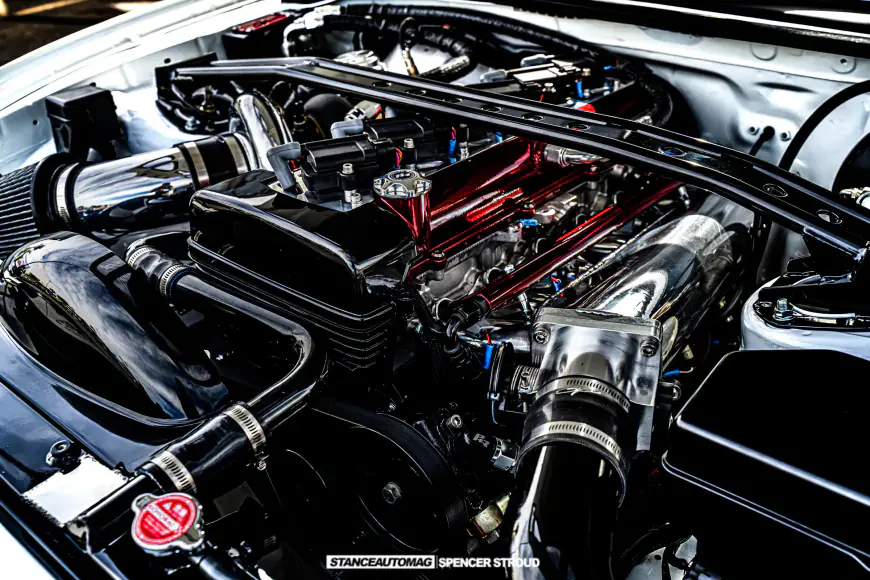

What Makes the 2JZGTE Different

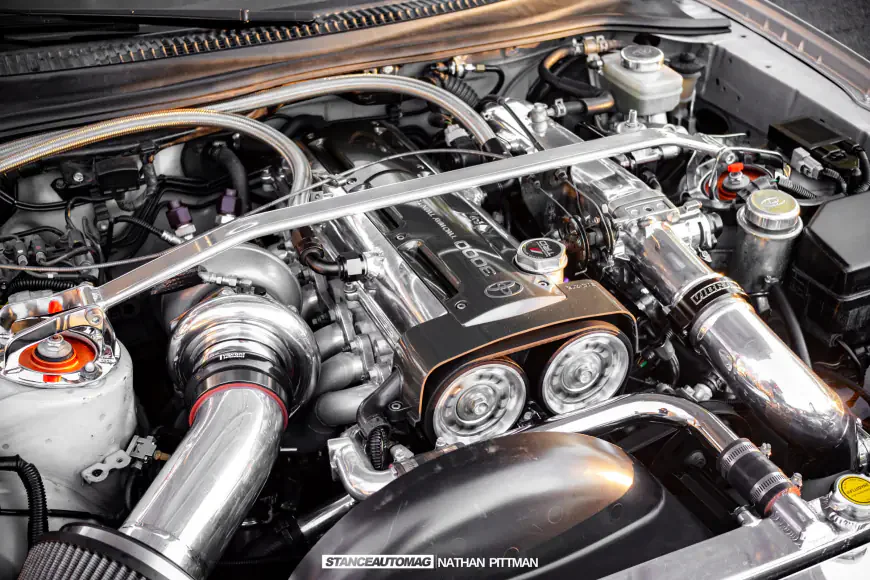

Toyota could have built the 2JZGTE with a lightweight aluminum block like most modern engines. Instead, they chose cast iron, adding weight but providing the rigidity and strength to handle cylinder pressures that would crack lesser blocks. The closed-deck design means the cylinders are fully surrounded by coolant passages, preventing the cylinder movement that causes head gasket failures in open-deck designs.

The crankshaft is forged steel with seven main bearings, counterweighted for balance, and strong enough to handle forces from much higher power levels. The connecting rods are also forged and feature oil spray nozzles directed at the piston undersides—a racing-derived cooling feature rarely seen in production engines. When engineers include details like this in a street car, they're planning for durability beyond what the marketing department promised.

The compression ratio sits at 8.5:1, intentionally lowered from what naturally aspirated engines use. This gives massive headroom for boost pressure increases without detonation concerns. Combined with factory forged internals and robust oil system design, Toyota essentially built an engine that could handle twice its rated power before anything approached its stress limits.

Factory Power: Understanding the Baseline

The official numbers vary depending on which market received the car. Japanese domestic market cars were limited to 276 horsepower due to the "Gentlemen's Agreement" between Japanese manufacturers, though everyone knew these cars made more. The actual output was 280 PS (about 276 hp) at 5,600 rpm and 318 lb-ft of torque at 4,000 rpm.

Export models to the United States and Europe quoted higher numbers because they weren't bound by Japanese regulations. US-spec Supras were rated at 320 horsepower and 315 lb-ft of torque, while European versions claimed 325 horsepower. These weren't different engines—just different testing standards and no need to artificially limit the published figures.

The later VVT-i engines from 1997 onward added variable valve timing on the intake camshaft, improving low-end torque delivery. These engines produced the same peak power but delivered 333 lb-ft of torque at a lower 3,600 rpm, making them feel stronger in everyday driving.

The Sequential Twin Turbo System

One of the most sophisticated aspects of the factory 2JZGTE is its sequential twin turbo setup. Contrary to popular belief, both turbos are identical in size—there's no "small" turbo and "big" turbo. Instead, the system runs one turbo below 4,000 rpm, then brings the second turbo online as engine speed increases, managed by a complex system of actuators and vacuum-controlled valves.

This approach provides excellent throttle response and minimal lag at low RPM while maintaining strong top-end power when both turbos are working. The downside is complexity. After 20 or 30 years, vacuum lines crack, actuators stick, and solenoids fail. Many builders eliminate this system entirely during modifications, but when it's working properly, it's an impressive piece of engineering that most modern twin-turbo setups still can't match for drivability.

How Much Power Can Stock Internals Handle?

This is the question everyone asks, and the answer depends on who you believe and what "reliable" means to you. Conservative builders say 600 horsepower at the wheels is the safe limit where you can expect years of trouble-free operation. Push to 700 wheel horsepower, and you're living on borrowed time unless everything else is perfect—the tune, the fuel, the maintenance schedule.

Some engines survive 750 or even 800 wheel horsepower on stock internals for extended periods. Others break pistons or bend rods at 650. The difference comes down to factors like turbo efficiency (more efficient turbos generate less heat and stress), fuel quality (E85 provides better knock resistance than pump gas), tuning expertise (conservative timing and safe air-fuel ratios matter enormously), and honestly, luck.

Beyond 800 wheel horsepower, you're not being smart running stock internals. At that power level, forged pistons, upgraded rods, and ARP head studs transition from "recommended" to "necessary unless you enjoy catastrophic failures."

Starting Simple: The BPU Approach

Before spending tens of thousands on a built engine, most Supra owners start with what the community calls BPU—Basic Performance Upgrade. This path maximizes the factory sequential twin turbos without opening the engine. You're looking at three-inch downpipes to eliminate the biggest exhaust restriction, a front-mount intercooler to reduce intake temperatures, some form of boost control to safely increase pressure, and proper tuning to tie it all together.

The factory turbos with these supporting modifications will deliver somewhere between 380 and 430 wheel horsepower depending on specific parts, boost levels, and dyno variations. That's a solid 100+ horsepower over stock, enough to make the car genuinely fast, and it maintains reasonable reliability when tuned properly. The total investment runs around three to five thousand dollars if you're doing the installation yourself.

This approach works well for people who want more power without the complexity and cost of major modifications. The car still drives like a factory vehicle, parts are relatively affordable, and you're not pushing components beyond their reasonable limits.

When Factory Turbos Aren't Enough

Eventually, many builders hit the wall of what the factory turbos can deliver and decide they want more. That's when single turbo conversions enter the picture. You're eliminating the entire sequential system—both factory turbos, all the actuators, vacuum lines, and complexity—and replacing it with one larger turbo that can flow enough air for much higher power levels.

The right turbo selection depends entirely on your power goals and how you'll use the car. A turbo sized for 500 to 550 wheel horsepower will spool almost as quickly as the factory setup, maintain excellent street manners, and provide reliable power for daily driving. Move up to a turbo targeting 700 wheel horsepower, and you'll notice more lag, but it's still manageable on the street with some adjustment to your driving style.

Push beyond 800 wheel horsepower, and you're getting into turbos that take time to build boost, require specific driving techniques to keep on the power, and really aren't ideal for stop-and-go traffic. These setups shine on the highway, road course, or drag strip but become tiresome in everyday situations.

Modern turbo technology from companies like Garrett, BorgWarner, and Precision has improved dramatically over what was available when these cars were new. Ball bearing turbos spool faster than older journal bearing designs, and better compressor wheel designs maintain efficiency across wider operating ranges. This means today's builders can run larger turbos with better response than previous generations could achieve with smaller units.

Supporting Modifications That Actually Matter

A bigger turbo alone won't get you there. The factory fuel system is already maxed out at stock power levels, so any meaningful increase requires upgraded fuel pumps and larger injectors. The stock ECU can't be reflashed or tuned effectively, meaning you'll need a standalone engine management system like AEM Infinity, Haltech, or Link G4+ to properly control fuel delivery, ignition timing, and boost levels.

The exhaust system needs attention—three-inch minimum diameter for moderate builds, three and a half or four inches for serious power. An external wastegate becomes important for boost control stability once you're past mild street modifications. The intercooler needs to be substantially larger than what the factory provided, especially if you're targeting over 600 horsepower where heat management becomes critical.

Ignition upgrades depend on power levels. The factory coil packs work surprisingly well up to about 500 horsepower with good ignition amplifiers, but beyond that, upgraded coils and careful spark plug selection with proper gap settings become important for maintaining reliable combustion at high cylinder pressures.

Building the Bottom End for Serious Power

Once you've decided that 800+ wheel horsepower is the goal, it's time to open the engine and install components designed for high-stress operation. Forged pistons replace the factory cast units, typically with slightly lower compression ratios (8.0:1 or less) to provide more safety margin for high boost pressure. Quality forged H-beam or I-beam connecting rods with ARP rod bolts replace the factory rods, providing the strength to handle higher cylinder pressures without bending.

ARP head studs replace the factory head bolts, providing improved clamping force to maintain head gasket seal integrity. A multi-layer steel head gasket or copper gasket appropriate for your compression ratio and power goals ensures reliability. Some builders chasing 1,000+ horsepower add main stud girdles or billet main caps to reinforce the main bearing caps against extreme forces.

The reality is that building a 2JZ bottom end isn't cheap. You're looking at five to ten thousand dollars just in internal engine parts before considering machine work, assembly labor, and all the supporting modifications needed to actually use that power. But when done properly with quality components and competent assembly, the result is an engine that can reliably produce power levels that would destroy most modern powerplants.

The Role of Camshafts

Factory camshafts are conservative, designed for emissions compliance, fuel economy, and broad appeal. Performance camshafts with increased duration and lift improve volumetric efficiency and shift the power band toward higher RPM where turbocharged engines make their best power. Mild cams with 256-264 degrees of duration maintain reasonable idle quality and drivability while supporting 650 wheel horsepower builds. More aggressive cams with 272-280+ degrees of duration provide the airflow for 900+ horsepower but create rough idle quality and narrow power bands more suited to track use than street driving.

All aggressive camshafts require upgraded valve springs and retainers to prevent valve float at high RPM. The factory springs simply can't handle the increased acceleration rates that aggressive cam profiles demand.

Transmission Reality Check

The 2JZGTE came with two factory transmissions, and the difference matters enormously for modified applications. The W58 five-speed is weak, maxing out around 350-400 horsepower before failures become common. It was never designed for turbo applications and doesn't belong behind a built engine.

The V160 six-speed Getrag transmission found in turbo six-speed Supras is substantially stronger, reliably handling 600-800 horsepower in conservative builds and sometimes surviving to 1,000 horsepower with careful tuning and driving. However, these transmissions are expensive to replace if they fail, and finding good used units becomes increasingly difficult as values climb.

Alternative transmission swaps like the Nissan CD009 six-speed from 350Zs or aftermarket Tremec T56 units require adapter plates and custom work but provide strong options for high-power builds. Each approach has tradeoffs in cost, drivability, and gear ratios.

Keeping It All Together

Making big power is one thing. Making it reliably for years is another. The cooling system needs attention—aluminum radiators with increased capacity, proper fans, and oil coolers for track use or high boost applications. Regular maintenance becomes non-negotiable. Synthetic oil changed every 3,000 to 5,000 miles, constant monitoring for boost leaks or oil consumption, and addressing any issues immediately before they cascade into expensive failures.

Professional tuning by someone experienced with 2JZ engines is absolutely critical. A proper dyno tune with conservative timing and safe air-fuel ratios provides the margin that keeps engines together. Chasing maximum dyno numbers by pushing timing advance and leaning out the fuel mixture might gain a few horsepower, but it also invites detonation and catastrophic damage.

Installing gauges for boost pressure, oil pressure, air-fuel ratio, and coolant temperature gives you the information to catch problems before they become disasters. Paying attention to what the engine is telling you matters more than most people realize.

What Does It Actually Cost?

If you're thinking about building a 2JZGTE, be realistic about budgets. A basic BPU setup with exhaust, intercooler, boost control, and tuning runs three to five thousand dollars and gets you to 400-ish wheel horsepower. A proper single turbo street build with quality parts, fuel system, standalone ECU, and professional tuning costs eight to fifteen thousand dollars and delivers 500-650 wheel horsepower with good drivability.

Serious performance builds targeting 700-900 wheel horsepower with forged internals, large turbos, and all supporting modifications require fifteen to twenty-five thousand dollars. Full race engines chasing 1,000+ horsepower with billet components, race-spec turbos, and bulletproof transmissions easily exceed fifty thousand dollars before you've even installed the engine in the car.

These numbers assume you're doing installation work yourself where possible. Shop labor adds substantially to every build level.

The Bottom Line

The 2JZGTE earned its legendary reputation through genuine engineering excellence, not internet hype. Toyota built an engine with margins that allow responsible enthusiasts to double or triple factory power while maintaining reliability that puts most modern engines to shame. But success requires respecting the platform, using quality parts, investing in proper tuning, and understanding that even legendary engines have limits.

Whether you're planning a mild BPU setup for weekend fun or a full race build targeting four-digit horsepower, the 2JZ platform provides the foundation. Build it smart, tune it right, maintain it religiously, and you'll understand why this thirty-year-old engine remains the benchmark that every other tuner motor gets measured against.

This build guide is brought to you by Stance Auto Magazine - your source for factual technical guides and automotive culture.

Related Articles

-

How to Choose the Right Turbo for a Street Supra - Turbo selection guide for daily-driven builds

-

V160 Manual Swap: Why and How for MKIV Owners - Transmission upgrade guide

-

MKIV Supra Brake & Wheel Upgrades That Work - Chassis upgrades to handle power

-

Street vs Track: Tuning a Supra for Daily Use - Balancing performance and usability

Call to Action

Do you have a build story like this one? Got a build on a budget? We want to see it. Submit your story to Stance Auto Magazine, and you could be the next featured owner showing the world how to do it right—without breaking the bank.

And hey, don’t forget to tag us on socials. Use #stanceautomag on Instagram, Pinterest and Facebook so we can see (and maybe feature) your ride.

Test Your JDM Car Knowledge and Take Our No. 1 JDM Car Quiz

Order Your Stance Auto Car Magazines From Our Amazon Book Store

Test Your Automotive Knowledge and Take Our No. 1 Car Quiz

Get Noticed Use our Hashtags - #stanceauto #stanceautomag #stanceautomagazine #modifiedcarmagazine

UKTM no: UK00003572459

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0

.png)

![[HOONIGAN] Ken Block's GYMKHANA NINE](https://img.youtube.com/vi/_bkX5VkZg8U/maxresdefault.jpg)

![[HOONIGAN] KEN BLOCK'S GYMKHANA SEVEN: WILD IN THE STREETS OF LOS ANGELES](https://cdn.motor1.com/images/mgl/2KlO4/s1/ken-block-london-tour-directors-cut.jpg)