BMW N54 & N55 Engine Guide: Which Is Better

Dive deep into the world of BMW's iconic N54 and N55 engines. Learn about their intricacies, strengths, and weaknesses, and explore responsible tuning practices to unleash their hidden potential.

Stay updated with the Latest Car News, in-depth Car Features, and expert Insights. Join Our Community of like-minded car enthusiasts.

Submit Your Car Build Stories Here!!

Order Your Printed Magazine Here!!

BMW N54 vs N55: The Complete Performance Engine Comparison Guide

The BMW N54 and N55 engines have carved a legendary niche within the automotive enthusiast realm, synonymous with exhilarating performance and extensive tuning potential. These turbocharged inline-6 powerplants have propelled countless BMW models to new heights, leaving an indelible mark on drivers and tuners alike. But what truly lies beneath the hood of these coveted engines, and how can you tap into their hidden potential responsibly?

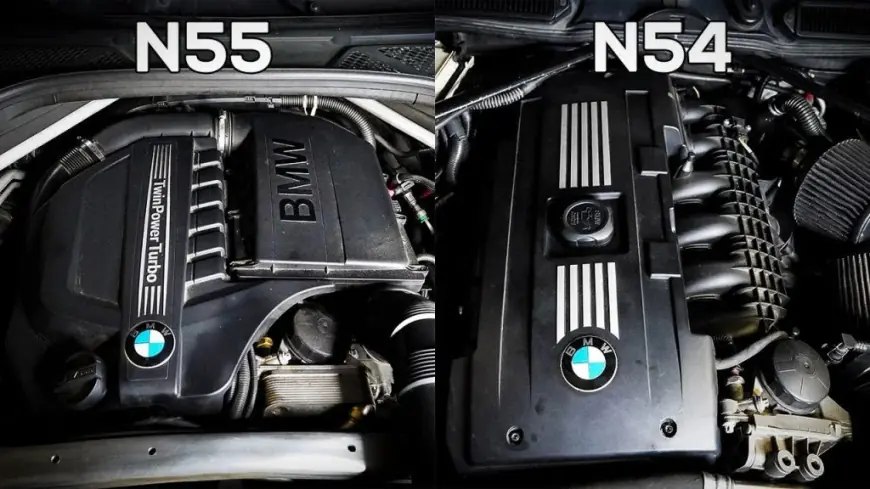

Unveiling the Beasts: A Deep Dive into N54 and N55 Architecture

While often categorized together, the N54 and N55 engines possess distinct characteristics that cater to different driving preferences. Introduced in 2006, the N54 marked a turning point for BMW, becoming the first mass-produced turbocharged engine to emerge from their stables since the 1980s. This pioneering mill boasted an aluminum block with iron cylinder liners for robust yet lightweight construction and employed a double-VANOS variable valve timing system. The N54's brilliance resided in its twin-turbo setup and ability to deliver exhilarating power, but concerns regarding high-pressure fuel pump failures, wastegate issues, and fuel injector problems arose over time.

BMW addressed these shortcomings with the introduction of the N55 engine in 2009 (production started in 2009, with 2010+ model years). This refined iteration incorporated a revised cooling system with additional webbing around cylinder sleeves to combat heat concerns, more reliable Bosch solenoid fuel injectors replacing the problematic piezoelectric injectors, and the addition of Valvetronic (variable valve lift) alongside the existing double-VANOS system for even more precise valve control and improved efficiency. While the N55 offered similar peak power to its predecessor, it delivered improved fuel efficiency (15% improvement), smoother power delivery, lower emissions (20% reduction), and a reputation for superior reliability.

Demystifying the N54 & N55: A Look Inside Their Inner Workings

To comprehend the true potential of these engines, delving deeper into their technical intricacies is crucial.

Turbocharger Configuration: The Key Difference

The most significant distinction between these engines is their forced induction setup. The N54 utilizes two smaller parallel turbochargers (true twin-turbo), while the N55 employs a single twin-scroll turbocharger. Both turbochargers are strategically positioned in the valley between the cylinder banks for optimal packaging and heat management.

This distinction translates to a notable difference in power delivery characteristics. The N54's twin-turbo setup offers exceptional responsiveness and delivers a more aggressive powerband, with both turbos working together to minimize lag. The N55's twin-scroll turbocharger separates exhaust gases from pairs of cylinders (1-3 and 4-6) to optimize efficiency, delivering a broader, more linear powerband while reducing complexity, weight, and cost.

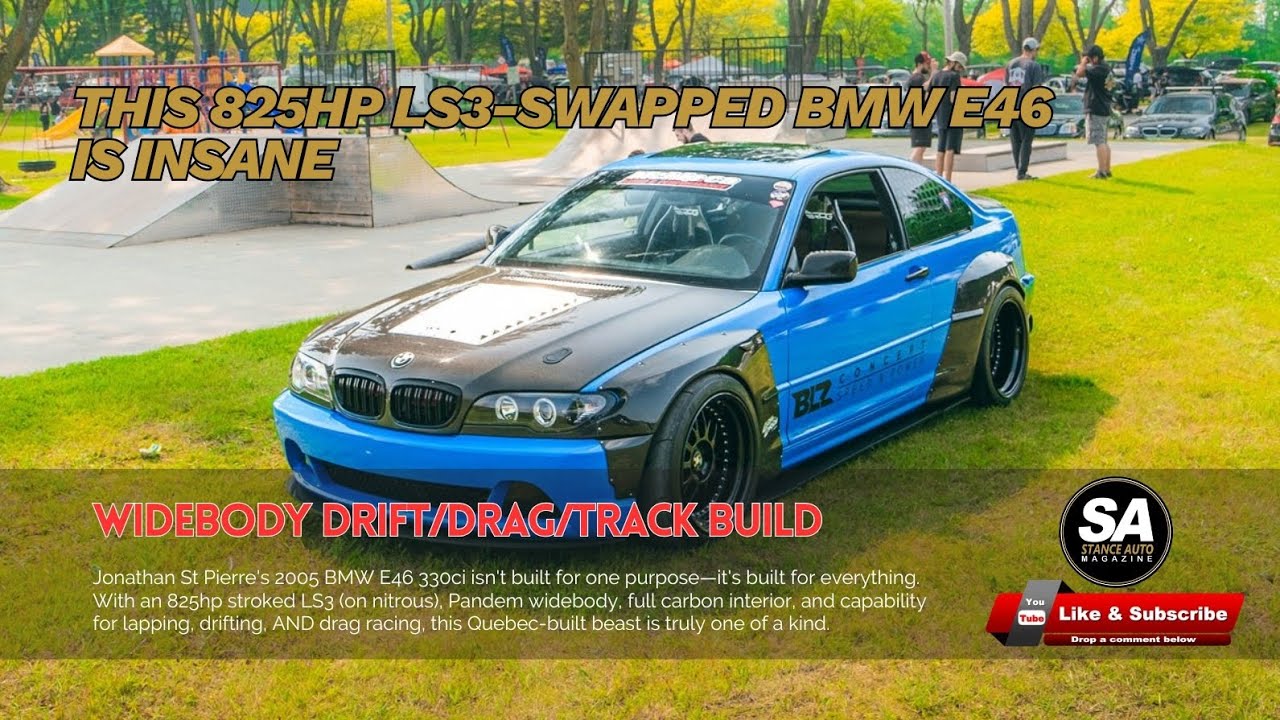

BMW E46 330ci Rocketbunny/Pandem - Benjamin Wieser

Valve Train and Timing Systems

Both engines feature BMW's double-VANOS variable valve timing system, but the N55 takes it further. The N54 already had double-VANOS (not single as sometimes claimed), but the N55 increased the adjustment ranges significantly—an additional 15 degrees on the intake side (from 54 to 70 degrees) and 10 degrees on the exhaust side (from 45 to 55 degrees).

The game-changer for the N55 was the addition of third-generation Valvetronic variable valve lift technology. This system allows precise adjustment of valve lift and duration, enabling the N55 to achieve significantly better fuel efficiency and throttle response across the entire rev range. The N54 did not have Valvetronic.

Internal Components and Construction

Both engines share the same basic architecture with aluminum blocks featuring iron cylinder liners in an open-deck design. However, there are critical differences in the rotating assembly:

N54 Internal Components:

- Forged steel crankshaft

- Forged connecting rods

- Cast aluminum pistons

N55 Internal Components:

- Cast steel crankshaft (3 kg lighter than N54's forged unit)

- Cast connecting rods

- Cast aluminum pistons with revised design

This is an important distinction: while the N54 features a stronger forged crankshaft and rods, the N55's cast components are still robust enough for significant power levels (up to 500-600 wheel horsepower) and contribute to cost reduction and weight savings.

Fuel Injection Systems

The N54 utilized BMW's High Precision Injection (HPI) system with expensive and complex piezoelectric fuel injectors. While technologically advanced, these injectors were notorious for failure and costly to replace.

The N55 switched to more conventional Bosch HEDV5.2 solenoid valve fuel injectors. While less sophisticated, these injectors proved far more reliable and cost-effective, addressing one of the N54's major pain points.

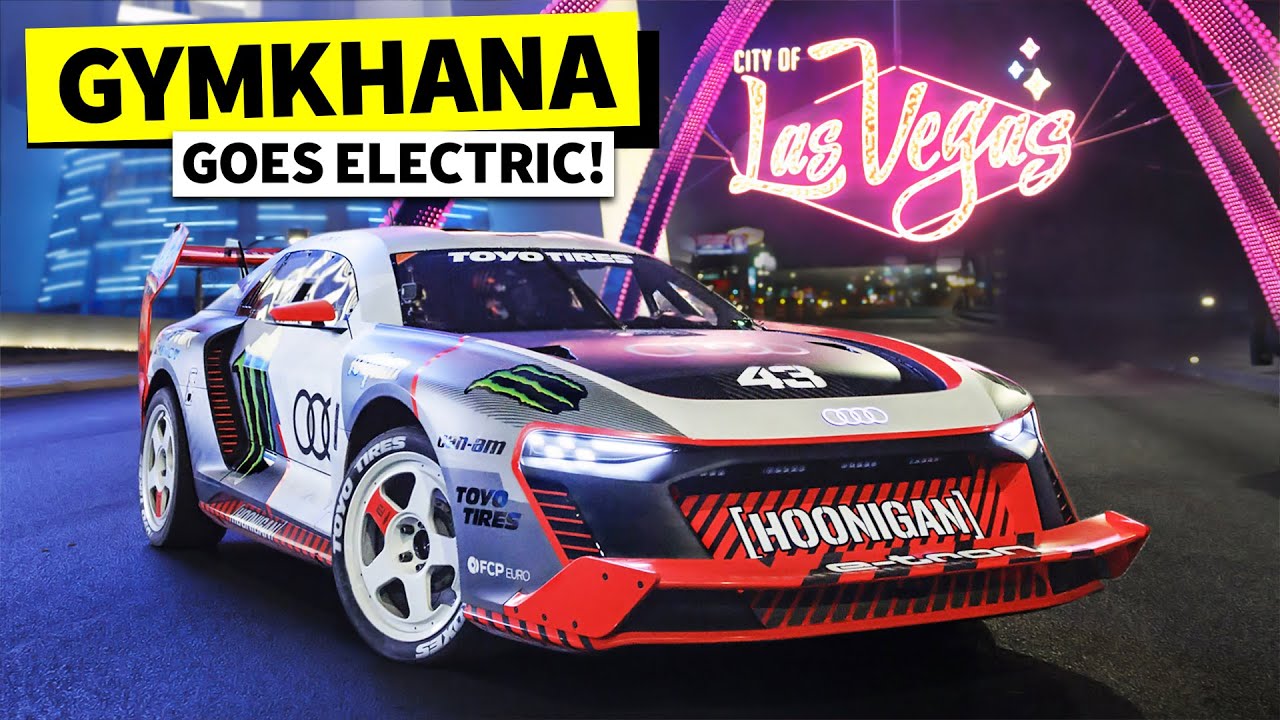

Have A Look At This Video For More Facts

Exploring the Tuning Landscape: Responsible Power Gains Await

The true magic of the N54 and N55 engines lies in their immense potential for performance upgrades. With a plethora of aftermarket parts and expert tuning expertise available, these engines can be transformed into true beasts, unleashing significant power gains and elevating the driving experience to exhilarating new heights. However, it's imperative to approach the world of tuning with caution and prioritize responsible practices to ensure optimal performance, reliability, and safety.

Stage 1 Tuning: Entry-Level Performance

This entry point into the tuning realm typically involves performance air intake systems, catless or high-flow downpipes, and ECU tuning (flash tune or piggyback systems like MHD or JB4). These modifications can yield moderate power increases of around 80-120 horsepower while maintaining daily drivability and reasonable reliability.

Stage 2 Tuning: Serious Performance

Building upon the foundation of Stage 1, this stage incorporates upgraded intercoolers (FMIC or VRSF), upgraded charge pipes, port injection kits, and more aggressive ECU tunes. Expect noticeable power gains in the range of 150-200 horsepower over stock. The N54's twin-turbo setup typically delivers slightly higher power figures than the N55 at this stage. Be mindful of potential warranty implications and the need for professional installation to ensure proper functionality and safety.

Stage 3 Tuning: Maximum Performance

This advanced stage delves into the realm of serious performance modifications. Upgraded turbochargers (single large turbo or upgraded twins for N54; hybrid or big single turbo for N55), high-flow fuel system upgrades (fuel pump, injectors, port injection), strengthened engine internals (forged pistons, rods, upgraded head studs), and aggressive ECU calibrations become the norm.

While capable of achieving phenomenal power gains exceeding 400+ wheel horsepower, Stage 3 modifications necessitate comprehensive knowledge, professional expertise, and supporting upgrades to brakes, suspension, transmission, and drivetrain components to handle the increased power effectively. At extreme power levels (800+ horsepower), cylinder support systems (CSS) or closed-deck conversions may be necessary to prevent block damage.

Crucial Considerations

Important Reality Check: The N54's twin-turbo design and forged rotating assembly make it the superior platform for extreme tuning. Mod-for-mod, the N54 will outperform the N55 due to its ability to move more air more efficiently. However, both engines are highly capable, with many N55 builds exceeding 500 wheel horsepower reliably.

It's paramount to remember that every engine reacts differently to modifications. Custom tuning by experienced professionals is highly recommended to ensure optimal performance, safeguard engine health, and prevent potential damage. Additionally, consider supporting modifications like upgraded braking systems, limited-slip differentials, and reinforced drivetrain components.

Maintaining the Thrill: Essential N54 & N55 Care

Even with the most meticulous tuning practices, proper maintenance remains paramount for the longevity and optimal performance of your N54 or N55 engine. Here are some key practices to religiously adhere to:

Frequent Oil Changes: Utilize high-quality synthetic oil (5W-30 or 0W-40) specifically formulated for turbocharged engines. Adhere to shorter oil change intervals (5,000 miles or less), especially with increased boost levels and aggressive driving habits.

Enhanced Cooling System Maintenance: Regularly inspect and service the cooling system components, including the radiator, intercooler, coolant hoses, and the electric water pump (a common failure point). Replace coolant at recommended intervals to maintain its effectiveness.

Spark Plug and Ignition Coil Replacements: Regularly replace spark plugs according to the manufacturer's specifications (typically every 30,000-60,000 miles) to ensure optimal ignition performance. Inspect ignition coils for signs of wear and tear, and replace them promptly if necessary—ignition coil failure is extremely common on these engines.

Fuel System Maintenance: For N54 owners, monitor high-pressure fuel pump (HPFP) performance and consider upgrading to a more reliable unit. Fuel injector issues are common on the N54. For N55 owners, the fuel system is generally more reliable but still requires periodic inspection.

Turbocharger Care: On N54 engines, wastegate rattle is extremely common and often requires upgraded wastegates. The N55's single turbo is generally more reliable but can still develop issues with the electronically controlled wastegate or diverter valve.

VANOS System Maintenance: VANOS solenoids can become oil-clogged over time, leading to performance issues or limp mode. Regular oil changes with quality oil help prevent this, but eventual replacement may be necessary.

Walnut Blasting: Both engines use direct injection, which leads to carbon buildup on intake valves over time. Periodic walnut blasting (every 60,000-80,000 miles) is recommended to maintain optimal performance.

The N54 & N55 Legacy: A Testament to Performance and Potential

The BMW N54 and N55 engines have undeniably carved their place in automotive history, captivating enthusiasts with their thrilling performance, extensive tuning potential, and legendary status within the car community.

Choose the N54 if you:

- Prioritize maximum tuning potential and aggressive power delivery

- Are willing to accept higher maintenance costs and more frequent repairs

- Want the most responsive twin-turbo setup for track or performance builds

- Don't mind dealing with common issues like HPFP failures, injector problems, and wastegate rattle

Choose the N55 if you:

- Want a more reliable daily driver with solid performance

- Prefer better fuel efficiency and lower emissions

- Are planning moderate tuning (under 500 wheel horsepower)

- Value lower maintenance costs and improved overall reliability

With responsible modifications, meticulous maintenance, and the expertise of qualified tuners, both engines can deliver exhilarating driving experiences for years to come. Whether you're a seasoned enthusiast or just beginning your exploration of the world of performance tuning, the N54 and N55 offer unique platforms to personalize your driving experience and unleash the true potential of your Bavarian beast. Remember, responsible tuning practices are paramount to ensure safety, reliability, and the continued enjoyment of these iconic engines.

Key Technical Specifications Comparison

|

Specification |

N54 |

N55 |

|

Production Years |

2006-2016 |

2009-2016 |

|

Turbocharger |

Twin parallel turbos |

Single twin-scroll turbo |

|

Block Material |

Aluminum with iron liners |

Aluminum with iron liners |

|

Deck Design |

Open deck |

Open deck |

|

Crankshaft |

Forged steel |

Cast steel (3kg lighter) |

|

Connecting Rods |

Forged |

Cast |

|

VANOS |

Double-VANOS |

Double-VANOS (increased range) |

|

Valvetronic |

No |

Yes (3rd generation) |

|

Fuel Injectors |

Piezoelectric (HPI) |

Bosch solenoid (HEDV5.2) |

|

Wastegate |

Vacuum-actuated |

Electronic (early) / Electronic (late) |

|

ECU |

MSD80/MSD81 |

MEVD17.2 |

|

Horsepower |

~300-306 hp |

~300-306 hp |

|

Torque |

~295-300 lb-ft |

~295-300 lb-ft |

|

Tuning Potential |

Excellent (800+ whp proven) |

Very Good (600+ whp proven) |

|

Reliability Rating |

Moderate (known issues) |

Good (improved over N54) |

|

Fuel Economy |

Good |

15% better than N54 |

|

Emissions |

Meets standards |

20% lower than N54 |

Other Useful Articles:

- Low and Slow, or Slammed and Sorry? A Cars Stance

- How do tilted wheels and tyres work on a modified car?

- Which brand of car tyre is the best?

- What is the best oil for my car?

- How can I save money on my car insurance?.

- What is the best car for the money?

- The Best Electric Cars for Your Money in 2023

Join the Discussion:

Share your thoughts and experiences with Modified Cars in the comments below! Let's create a space for informed discussion and responsible car modifications.

Check Out Our Digital Magazines Here!!

Do you Need A Freelance Photographer? Our Photographers Are Available For Hire

Get Noticed Use our Hashtags - #stanceauto #stanceautomag #stanceautomagazine #stanceautomedia

UKTM no: UK00003572459

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0

.png)

![[HOONIGAN] Ken Block's GYMKHANA NINE](https://img.youtube.com/vi/_bkX5VkZg8U/maxresdefault.jpg)

![[HOONIGAN] KEN BLOCK'S GYMKHANA SEVEN: WILD IN THE STREETS OF LOS ANGELES](https://cdn.motor1.com/images/mgl/2KlO4/s1/ken-block-london-tour-directors-cut.jpg)